Product

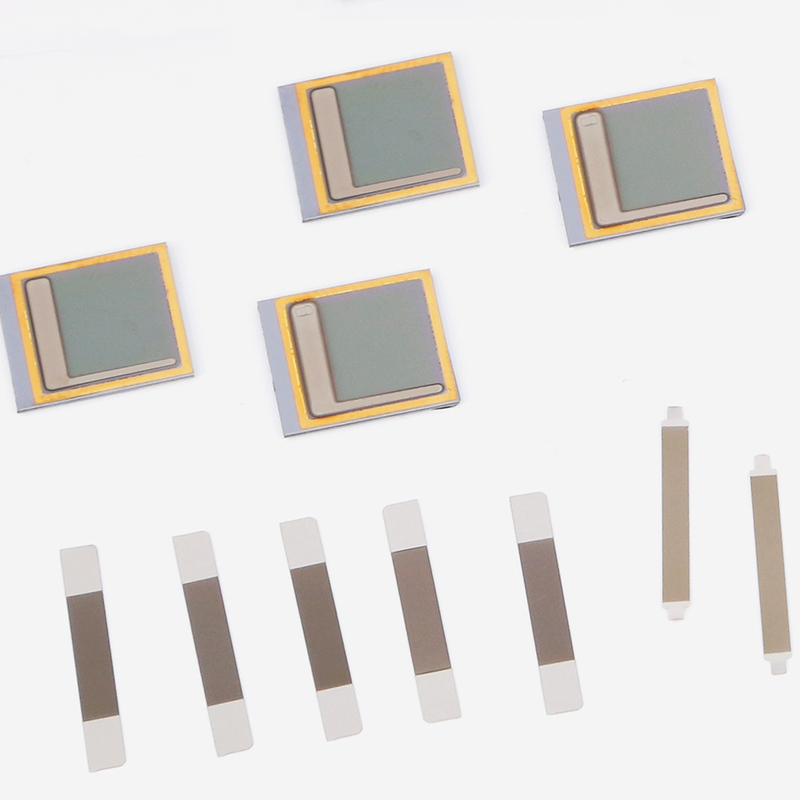

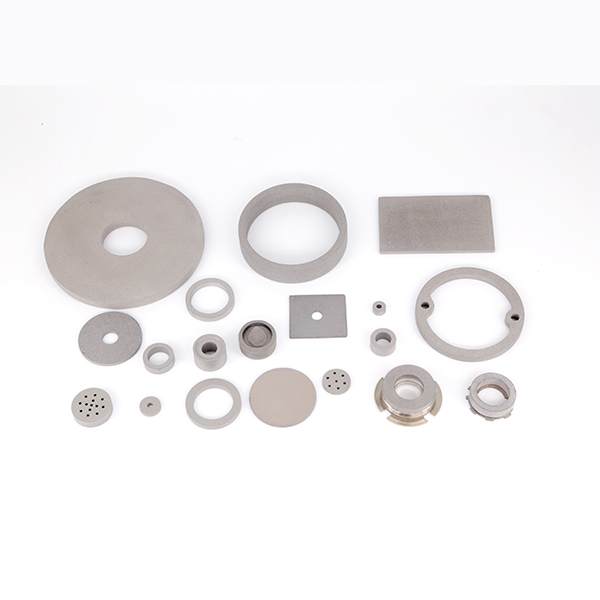

Sintered Porous Getter

Features and Applications Sintered Porous Getter is sintered by all kinds of non-evaporable getter alloys at high temperature. It is characterized in low activation temperature, high gettering rate, big sorption capacity, good compactness, and less loose particles. Our Sintered Porous Getter i...

Description

Sign

Features and Applications

Sintered Porous Getter is sintered by all kinds of non-evaporable getter alloys at high temperature. It is characterized in low activation temperature, high gettering rate, big sorption capacity, good compactness, and less loose particles. Our Sintered Porous Getter is added with high efficiency activator and anti-sintering agent so as to improve its gettering performance. Its size and shaped can be made according to customers’ requirements. It also can carry a heater so that it can be used in where it cannot be activated by high frequency or heat radiation. The getter is applied to IR detector Dewar, X-Ray tubes, and so on.

Basic Characteristics and General Data

1.No Heater Type

| Type | O.D.(mm) | L.D.(mm) | H(mm) | Outlines |

| TM7D260X | 6.9 | 3.1 | 3.1 | PIC 1 |

| TM8D150X | 7.9 | 3.6 | 1.25 | PIC 1 |

| TM8D240X | 8 | 2 | 1.8 | PIC 1 |

| TM10D620X | 9.9 | 4.9 | 3.6 | PIC 1 |

| TM10D660X | 10.5 | 6.1 | 3.85 | PIC 1 |

| TM10D710X | 10 | 6.1 | 4.9 | PIC 1 |

| TM12D360X | 12 | 8 | 2 | PIC 1 |

| TM12D450X | 11.9 | 5.3 | 1.7 | PIC 1 |

| TM12D720X | 12 | 8 | 4 | PIC 1 |

| TM12D940X | 12.35 | 7.1 | 3.9 | PIC 1 |

| TM13D1030X | 12.6 | 8.8 | 5.5 | PIC 1 |

| TM13D1880X | 12.5 | 5.9 | 7.6 | PIC 1 |

| TM15D400X | 14.9 | 9.1 | 1.3 | PIC 1 |

| TM15D950X | 15 | 10 | 3.5 | PIC 1 |

| TM15D1300X | 15 | 8.5 | 3.9 | PIC 1 |

| TM15D1420X | 15 | 8.5 | 4 | PIC 1 |

| TM15P1480X | 15 | / | 4 | PIC 2 |

| TM16D870X | 15.8 | 5.3 | 1.7 | PIC 1 |

| TM18D2350X | 17.9 | 8.1 | 4 | PIC 1 |

| TM19D2250X | 19 | 10.2 | 3.8 | PIC 1 |

| TM20D1410X | 20 | 6.3 | 1.7 | PIC 1 |

| TM21D1250X | 21 | 15 | 2.5 | PIC 1 |

| TM21D2200X | 21 | 14 | 4 | PIC 1 |

| TM25D1930X | 24.9 | 6.2 | 1.7 | PIC 1 |

| TM25D5700X | 24.8 | 14.2 | 6 | PIC 1 |

| TM26D7780X | 25.85 | 10.2 | 6 | PIC 1 |

| TM28D6820X | 27.6 | 14.3 | 5.3 | PIC 1 |

| TM32D6650X | 31.7 | 21.3 | 6 | PIC 1 |

| TM45D8000X | 45 | 39 | 10 | PIC 1 |

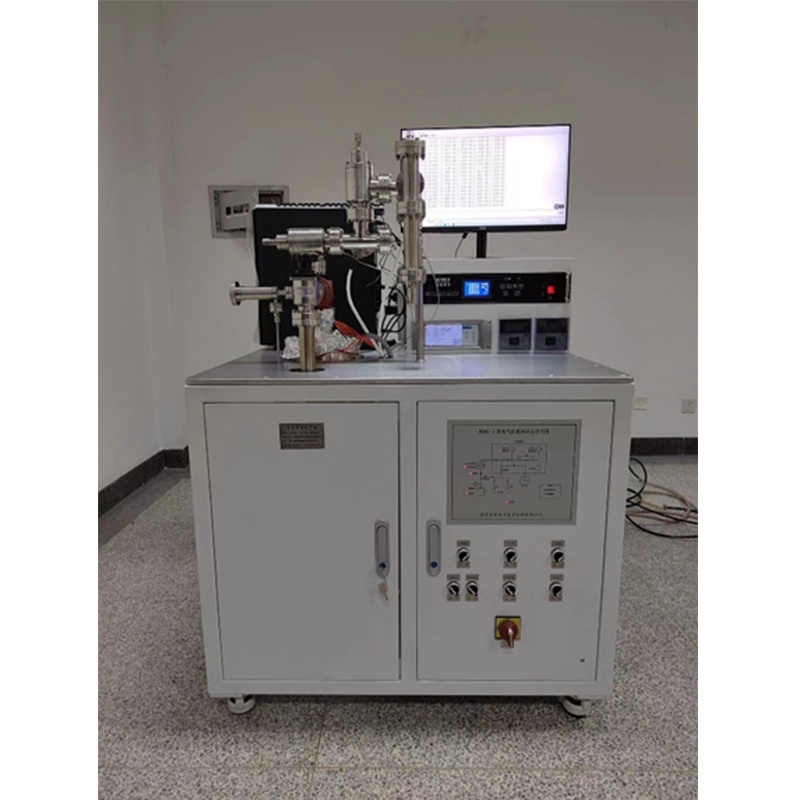

2.With Heater Type

| Type | Alloy | O.D.(mm) | L2(mm) | L1(mm) | Outlines |

| ZZV1IM10H-C | Zr/Zr-V-Fe | 1 | 4 | 12 | PIC 3 |

| ZZV2IM40H-C | Zr/Zr-V-Fe | 2 | 4 | 10 | PIC 3 |

| ZZV2IM70H-C | Zr/Zr-V-Fe | 1.85 | 7.9 | 20 | PIC 3 |

| ZZV2IM70HTL-C | Zr/Zr-V-Fe | 1.8 | 7.4 | 18 | PIC 4 |

| ZZV3IM100H-C | Zr/Zr-V-Fe | 2.9 | 6.65 | 20.5 | PIC 4 |

| ZZV3IM150H-C | Zr/Zr-V-Fe | 3.3 | 7.8 | 20.5 | PIC 4 |

| ZZV3IM150H-CK | Zr/Zr-V-Fe | 3 | 7.1 | 17 | PIC 4 |

| ZZV4IM290H-C | Zr/Zr-V-Fe | 4 | 7.9 | 17 | PIC 4 |

| ZZV4IM290H-CB | Zr/Zr-V-Fe | 4 | 7.1 | 17 | PIC 4 |

| ZZV4IM290H-CK | Zr/Zr-V-Fe | 4 | 7.8 | 17 | PIC 4 |

| ZZV7DM650UT-C | Zr/Zr-V-Fe | 7.8 | 5.5 | 18.5 | PIC 7 |

| TM8DM800U | Ti/Mo | 8.4 | 8.5 | 22 | PIC 5 |

| ZZV8DM1000U-C | Zr/Zr-V-Fe | 8.2 | 9 | 17.5 | PIC 5 |

| ZZV8DIM1000I-C | Zr/Zr-V-Fe | 8.3 | 8.1 | 15.5 | PIC 6 |

| ZZV10DM1200UT-C | Zr/Zr-V-Fe | 10 | 10.4 | 23.5 | PIC 7 |

| TM14DM1800U | Ti/Mo | 14.2 | 9 | 21 | PIC 5 |

| ZZ14DM2100U | Zr/ZrAl | 14.2 | 9 | 21 | PIC 5 |

| ZZ14DM2100U-C | Zr/ZrAl | 14.2 | 9 | 21 | PIC 5 |

| ZZ14DM2100U-C2 | Zr/ZrAl | 14.2 | 9 | 21 | PIC 5 |

| ZZV14DM2800U-C | Zr/Zr-V-Fe | 14.2 | 9 | 21 | PIC 5 |

| ZZV16DM5000U-C | Zr/Zr-V-Fe | 16 | 10 | 17 | PIC 5 |

| ZZV20DM1200U-C | Zr/Zr-V-Fe | 20 | 3.5 | PIC 9 | |

| ZZV22DM2700U-C | Zr/Zr-V-Fe | 22 | 7 | PIC 8 | |

| ZZV26DM3200U-C | Zr/Zr-V-Fe | 26 | 4.5 | PIC 10 |

Recommended activation conditions

| Alloy | Activation Temp℃ | Operating Temp ℃ | Typical Sorption Curves |

| Zr / Zr-V-Fe | 400 - 800 | Room Temperature 300 | Graph 1 |

| Ti / Mo | 400 - 800 | Room Temperature 300 | Graph 2 |

| Zr / ZrAl | 700 - 900 | Room Temperature 300 | Graph 3 |

Graph1: Typical Sorption Curves of Zr / Zr-V-Fe

Activation:500℃×10 min Sorption:H2, 25℃, P=4×10-4Pa

Graph2: Typical Sorption Curves of Ti / Mo

Activation:500℃×10 min Sorption:H2, 25℃, P=4×10-4Pa

Graph3: Typical Sorption Curves of Zr / ZrAl

Activation:900℃×10 min Sorption:H2,25℃, P=4×10-4Pa

Caution

1. Sealed getter shall be stored in dry clean environment with a relative humidity lower than 75%m and no erosive gases.

2. The getter is stable in the air, but dust, vapor and erosive gas shall be avoided. To assemble the getter, fiber gloves are forbid and disposable latex gloves are recommended.

3. The getter shall be used in time after aluminum foil bag or the can is unsealed.

4.The getter temperature shall not be more than 200℃ in the air, otherwise it will self-ignite.

5. The support of the getter heater shall not be shaken heavily, and it shall be careful while welding the getter lest the fall-off of the getter alloy. Special attention must be paid to avoid any direct contact between the bare metallic leads and the gettering material where the leads enter the getter body: in fact this would cause dangerous short circuits.

6. The getter can perform only after it is activated. Usually, we suggest activation before the sealing of a device and a device shall be sealed soon after the getter is activated. During the life time of a device, the getter can be re-activated.

7. The quality guaranty time for sealed getter is one year from the manufacturing date.

contact us

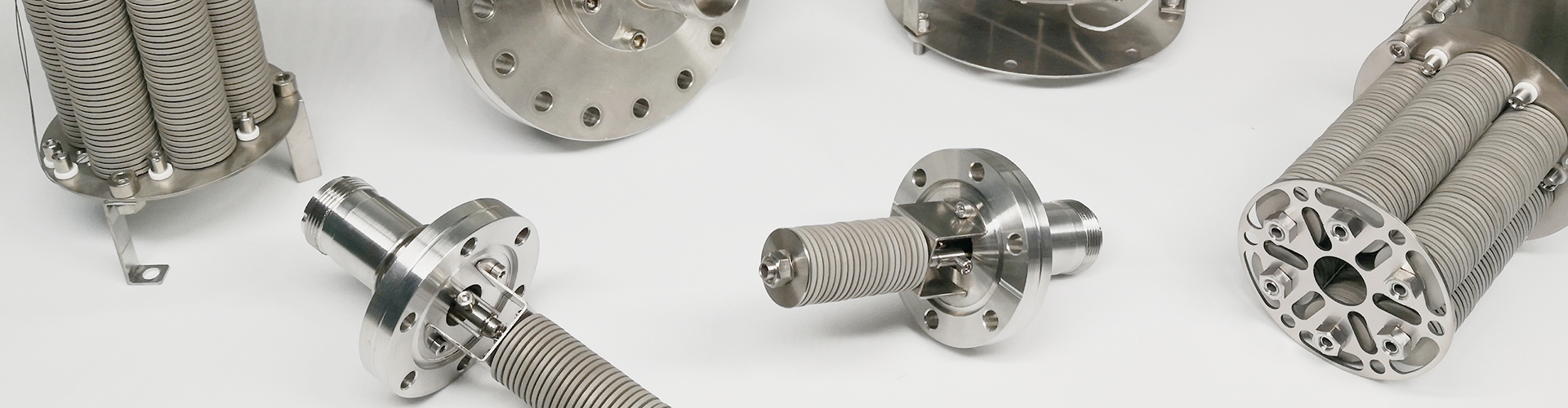

Related popular products

Please leave us a message.

Please enter your email address and we will reply to your email.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur